No I’m not here to talk about that moderately successful ice skating film starring Will Ferrell, this post is all about the wire processing blade and its properties.

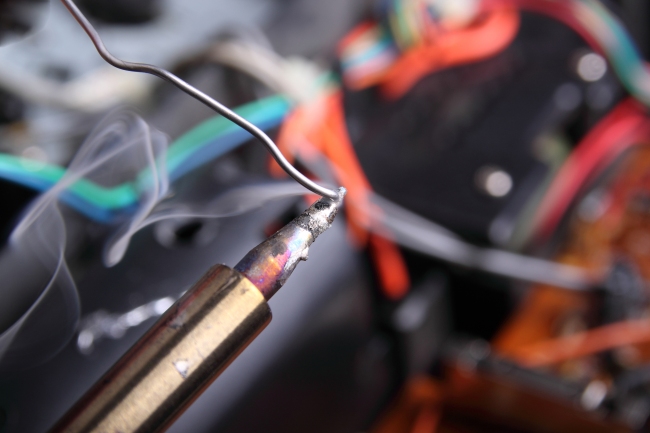

As published in this month’s Assembly Mag, the humble blade does not get much attention these days, yet the importance of it remains vital to the success of your wires and cables.

Choose the wrong blade and your wire can become feathered – where strands of wire have been cut out completely, if the blade cuts too deep it can leave marks in the conductors or it may not strip the wire at all.

“For decades, manufacturers have relied on three types of blades to strip and cut wire: V, rotary and die. All blades are made of hardened tool steel, but each type is unique in design, function and capability” 1

So how do we know which blades to use for each wire and cable we use?

The first blade and for me the most common in cutting and stripping wires and cables is the V-Blades. Versatile and variable, these blades feature a 90-degree V configuration that provides good quality stripping and cutting of a wide range of wire sizes (26 to 10 AWG) and insulation types (PVC, Teflon, fiberglass)

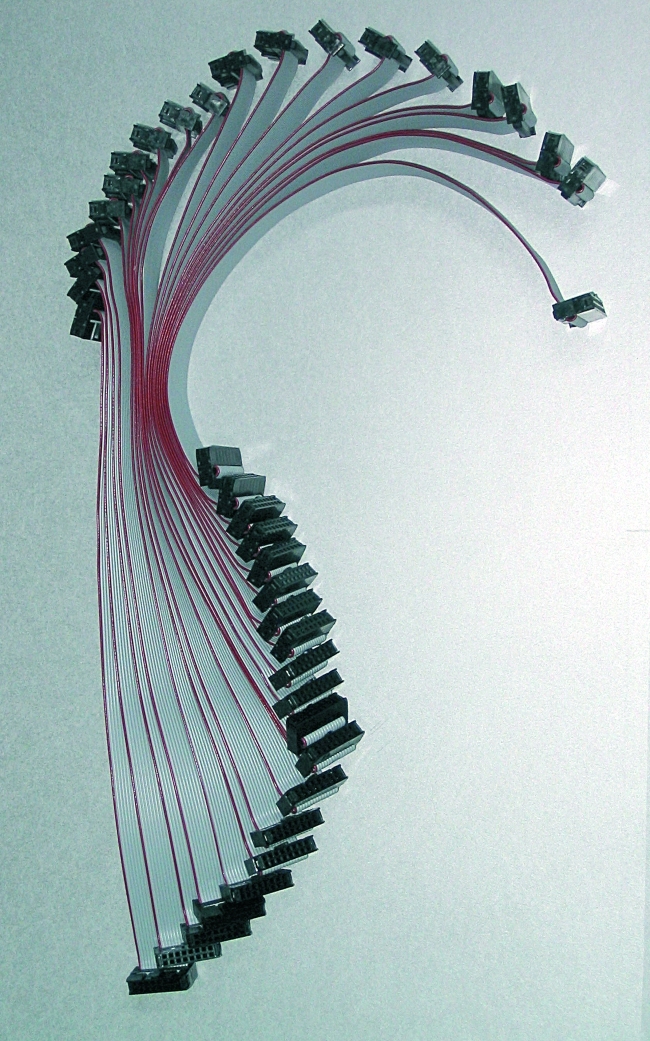

V blades are used in sets (top and bottom) that bypass each other to cut wire. Stripping V blades penetrate the insulation at four points that, when connected, form a diamond 2. V-Blades should be the main choice of blade in most wire and cable processing applications.

Rotary blades, interestingly, are square, not round. Their name stems from the fact that the blades rotate around the insulation to strip it. With similar properties to the V-Blades, rotary tooling can cut up various sized wire and cable but at a much slower and less efficient pace. Interestingly, experts say these blades are not designed to cut wire. Instead they mark wire which is slightly thicker and rounder in shape.

Die blades are custom made to strip or cut a specific AWG wire. The most common die blade for stripping is the collinear radius (CL-R) type. It features a ground half circle at the center of its straight shear edge 3.

When a set of duplicate CL-R blades are closed around the wire, the circle’s radius matches the wire conductor exactly. This perfect fit produces precise stripping and clean shoulders without any conductor damage.

Die blades are often required for stripping tougher insulations, standard die blades strip 4 to 30 gauge wire, ground-edge blades strip 8 to 26 gauge wire and precision blades with guide strip 28 to 36 gauge wire.

So to conclude, the right blades are critical to your product’s success.

The most important consideration is the application range that it must process. Some applications only require a machine that can measure, cut to length, and strip one or both ends of a wire or cable. This is considered basic and can be done using a machine with a cutter head that can only accept one set of blades. In this case use the V-Blades.

With the rotary blades, “the rotary stripping head can be programmed to make incisions at any depth into the insulation, this design eliminates the need for changing blades (radius blades, die blades, etc.) when processing different wire or cable sizes. But the production rate is somewhat slower“4

The die blades should only be used when faced with cutting wire regularly that has tough insulation. It can cope with more material thickness that standard V-blades and rotary blades can’t.

HOPE THAT HELPS!!!

1 = http://www.assemblymag.com/articles/91830-cutting-it-close

2 = http://www.assemblymag.com/articles/91830-cutting-it-close

3 = http://www.assemblymag.com/articles/91830-cutting-it-close

4 = http://www.schleuniger-na.com/en-us/news-events/news/news/2012/03/01/choosing-the-right-cut-and-strip-machine-its-all-about-the-apps/

1

1